This blog is aimed to provide some background on the sampling process…

Introduction to Water Sampling

The accuracy of the results obtained from water sampling relies principally on ‘doing the basics well’. Whilst it is imperative to understand the; how, what, why, where and when we take water samples, these considerations are underpinned by two key requirements:

- The sampler must follow the approved technique when sampling from an outlet;

- As far as reasonable and practicable, think about all aspects of the sampling environment that may pose a cross-contamination risk.

By following the approved methodology/sampling technique coupled with the adoption of good sampling practice, to mitigate factors that may otherwise cross-contaminate the sample taken, it is possible to consistently obtain results that accurately represent the water quality within the outlet sampled.

Sampling Processes

Guidance is available from British Standards and the Environment Agency, which both offer practical advice on how to sample and monitor from hot and cold water services (BS 8554:2015). BS 7592:2022 describes how to sample specifically for Legionella bacteria in water systems and laboratory advice surrounding the determination/detection and enumeration of aquatic bacteria is found in Microbiology of Drinking Water – ‘Blue Book’.

Therefore ‘sampling processes’ may be defined by two parts:

- Operational considerations when sampling outlets;

- Laboratory methodologies and associated diagnostics when determining the ‘target organism’ presence.

This blog will focus on the first part and outline the operational considerations of taking a water sample following the aforementioned British Standards.

Legionella Sampling Rationale

For legionella sampling, it is advised that water samples are undertaken to demonstrate the effectiveness of the established control scheme and are not considered a control measure themselves. Therefore, superfluous sampling (‘fishing for results’) is not advised. The Water Safety Group should use Legionella risk assessments to determine when and where to test, which may include the following circumstances;

- When storage and distribution temperatures do not achieve those recommended and systems are treated with a biocide regime, testing should be carried out monthly, although that frequency may be altered depending on the results obtained;

- In systems where the temperature or biocidal control regimes are not consistently achieved, weekly checks are recommended until the system is brought under control, after which the frequency of monitoring can be reviewed;

- When a nosocomial (a disease originating in a hospital) outbreak is suspected or has been identified;

- Where there are at-risk patients with increased susceptibility.

For Pseudomonas aeruginosa, it is advised in the HTM04-01 that samples are taken every 6 months from outlets in augmented care units. Most care that is designated as augmented will be that where medical/nursing procedures render the patients susceptible to invasive disease from environmental and opportunistic pathogens such as Pseudomonas aeruginosa and other alert organisms.

The water outlets to be sampled should be those that supply water that:

- Has direct contact with patients;

- Is used to wash staff or visitors hands; or

- Is used to fill or clean equipment that will have contact with patients or visitors as determined by risk assessment.

Although, guidance for Scotland ‘Guidance for neonatal units (NNUs) (levels 1, 2 & 3), adult and paediatric intensive care units (ICUs) in Scotland to minimise the risk of Pseudomonas aeruginosa infection from water’ does not advocate routine sampling for Pseudomonas aeruginosa.

For general bacteriological monitoring, it is advised in the HTM04 that routine samples are not necessary as no direct association with the presence of waterborne pathogens. Although testing may be considered necessary where there are taste, discolouration, or odour problems.

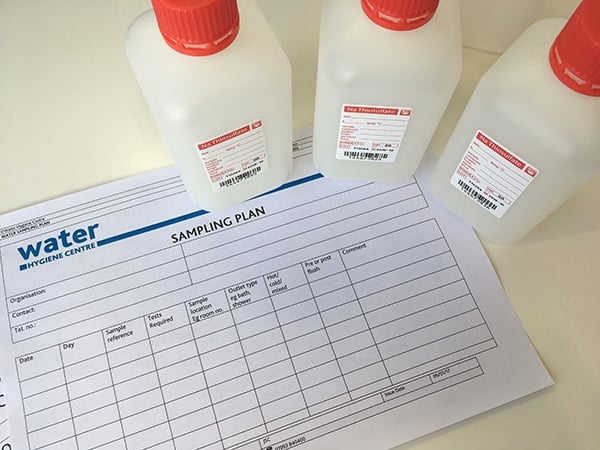

Sampling Plan

Before water sampling begins there should first be a strategy/rationale for the works and HTM 04-01 Part B Paragraph 10.2 guides in this regard. Moreover, it is advised that water samples should be taken from the nearest and farthest points on a water distribution system, known as the sentinel outlets.

As a minimum, samples should be taken as follows:

- From the cold water storage and the furthermost outlet from the tank;

- From the calorifier flow, or the closest tap to the calorifier, and the furthermost tap on the hot water service circulating system;

- Additional samples should be taken from the base of the calorifier where drain valves have been fitted, if safe to do so due to scald and mechanical risks;

- Additional random samples may also be considered appropriate where systems are known to be susceptible to colonisation in line with BS7592-2022

Sampling from outlets at the extremities of a distribution system offers insight with respect to the microbiological quality of water between these sentinel points, thus removing the need to sample every outlet in between. The sampling plan should also consider the need to sample any additional outlets, such as those that represent remote parts of the system e.g., an outlet positioned at the end of an unusually long pipe run.

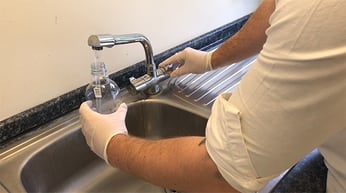

Collecting Samples

When collecting a water sample, the aim is it should be representative of the sample location at the time of collection; hence the importance of using the approved sampling technique and mitigating any risk of cross-contamination.

Equally important is the handling of the sample once it has been taken to minimise change before the laboratory analysis begins. Therefore, careful consideration should be given to the following:

- Choice of sampling point;

- The possible presence of biocides, such as chlorine;

- Whether or not there is a need to disinfect the sampling point;

- Location & timing of the sample – concerning normal operating conditions & control measures of the system. Especially if secondary disinfection is commonplace;

- The type & quantity of sample to be taken – considering the requirement for different volume samples dependent upon the target organism. For example; Legionella samples are usually collected in either 500ml or 1-litre containers whereas Pseudomonas analysis only requires a 100ml sample and may be collected in a 100ml to 500ml container depending on the laboratory;

- Storage of the samples (this is detailed in Part 2 of the blog - Water sampling technique);

- Transportation of the water samples (this will be detailed in Part 2 of the blog - Water sampling technique).

Sampling Tips to Remember

Sampling can provide valuable information on the efficacy of the control scheme, which pre-planned maintenance (PPMs) such as temperature monitoring may form a part. However, this will only be true if the sampling programme is properly planned and executed following available guidance.

Random ‘fishing for results’ is not recommended. Sampling should be carried out in response to a specific need with a clear underlying rationale.

When sampling has been carried out as a result of a previous loss of control, once it’s been accepted that control has been regained, then sampling following the original regime should resume – supported by the site-specific Legionella risk assessment and the organisational Water Safety Plan (WSP).

The water sampling technique and the chain of custody associated with microbiological testing will be discussed in Legionella sampling: Part 2 - technique & chain of custody.

> Watch our Legionella Sampling Academy Video

Feel free to reach out if you have any questions about the issues mentioned above or if you would like to consult with one of our experts on water hygiene.

Editors Note: The information provided in this blog is correct at the date of original publication – December 2022.

© Water Hygiene Centre 2022