It is important that those managing or planning the Legionella flushing needs of any Infrequently used outlet consider the task fully, they should not simply apply the controls listed in HSG 274-part 2 Table 2.1, but review the outlet/point fully. Ask if this point is required? Can it be removed? Or can its use be changed/revised to encourage use? In other words, look to “Eliminate the risk”.

Understanding the needs.

The identification of the need to flush outlets routinely coincides with the identification of either a need to service an engineering point (i.e., filter, capped end, or naturally slow flowing point -vending/washing machines/urinals etc), manage building use (i.e., mothballing, project or alterations works etc) or to control an identified risk from the Legionella risk assessment, its review or identification of such an outlet or point following the periodic pipework inspection and review.

The identification of the need to flush outlets routinely coincides with the identification of either a need to service an engineering point (i.e., filter, capped end, or naturally slow flowing point -vending/washing machines/urinals etc), manage building use (i.e., mothballing, project or alterations works etc) or to control an identified risk from the Legionella risk assessment, its review or identification of such an outlet or point following the periodic pipework inspection and review.

It must be acknowledged that removal or change cannot always be possible as the welfare needs of water as well as the requirements to manage the wholesome (water fit for human consumption) supply places constraints on the minimum levels of outlets or access to specific areas of water systems which must be available in the workplace. Hence the importance of both a written scheme as noted by HSG 274 Appendices 2.2 and the Water Safety Plan required to manage water systems in the workplace, especially as the ACoP L8 may note it fails to cover these needs.

Understanding how to manage or improve service.

Routinely, infrequently used outlets may be simply added to a list. This often results in staff or contractors attending the area on a weekly or twice a week base as part of their Legionella flushing regime when they undertake flushing for a set time, typically around 2-5 minutes. Actions are normally recorded either via a handheld device or by a tick on a list to indicate the task has been done.

How do these typical actions allow you to review or gain awareness of whether the flushing is or is not controlling the recognised risk?

If you are adding the needed flushing task to an outlet it will become an area which needs to be reviewed. Trending should highlight if the flushing is required, if sampling or if additional/specific Legionella sampling is required to ensure the risk is under control.

What have you or what can you learn from simple flushing and recording a tick? If nothing, why are you doing it?

If it is decided the task is required, then plan it correctly. Any task undertaken should control or improve the water systems. Whatever you do should be reasonable, practicable, simple, and achievable.

However, your record should also allow you to measure (review) the service not simply say it’s done!

- Identify what you are looking to achieve from the task i.e., improve or manage water quality. Measure inlet or storage temperature, and record this as the set point/target to be achieved;

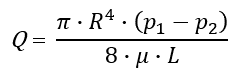

- Measure and monitor flow rate. The correct method is not simple i.e., “flow rate = π X pressure difference X pipe radius 4 X liquid viscosity / 8 X viscosity X pipe length”.

Or using a measuring jug and a stopwatch set for six seconds open a tap to full flow and measure the water collected in the 6 seconds, multiply the volume by 10, for example if a jug collects 250ml in 6 seconds x 10 this is 2.5ltr a minute. This is not the actual volume but a simple volume; - Periodically review the flow rate in the same manner. Flow rate lower? Consider strainers or the filter condition or increase the flush time. Flow rate up, consider decreasing flush time;

- Consider water condition: Odour, Colour, Taste Temperature

|

Odour, |

Has the room on entry got a stale smell, this may indicate that the outlets trap is dry, the frequency of flushing may need to be adjusted |

|

Colour, |

Get those undertaking the task to note if the water has any visible colour, most common are: Blue: possible chemical backflow Brown: Possible dirt/mud entering a burst or open pipe or signs of Iron Green/Yellow: Possible copper deposit/If using CLO2 dispensing raw chemical entering the chamber Milky white: Settle upwards possible Air/settle down possible scale |

|

Taste |

Is the water fresh and tasteless or has it a TCP/chemical or leave a tingling on the tastebuds |

|

Temperature |

Especially when flushing, the temperature should be monitored, this helps towards determining if the outlet is infrequently used or not as cold water may increase in temperature and hot significantly, to become noticeable |

|

Condition |

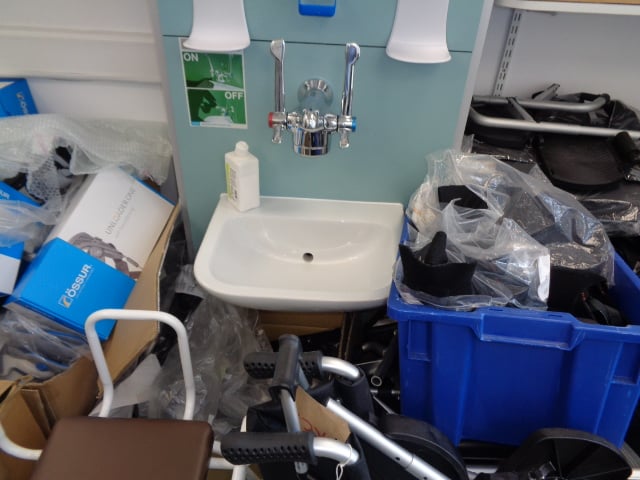

Report the state of the outlet and the surroundings: Have bins been placed close by, is the outlet accessible, signs of scale, signs of frequent use? Outlet showing signs of corrosion or pealing chrome. Signs of seepage or leaking drains, signs of non-use outlet being used as a shelving unit, light switches no working on entering the room, dust or dirt within the outlet |

WaterSafe offers advice over Taste and Odour as well as other guidance over water systems which can be considered as part of the legionella flushing regime. The WaterSafe film clip available in the link focuses on the reasons behind strange tastes and smells affecting homeowners’ drinking water, and what can be done to prevent them. It features chlorine, metallic or antiseptic-tasting water, a musty or sewage smell and bitter water.

The clip also features advice from Affinity Water and the Drinking Water Inspectorate (DWI) for England and Wales. It follows the release of the annual report of the DWI, which shows that while tap water quality in the UK remains among the best in the world, a small number of samples fail taste and smell tests.

A significant proportion of these failures can be linked to poor plumbing or bad practices, wrongly connected pipework, poor materials and fittings, inadequate protection from water ‘flowing back’ into internal pipework from dishwashers and toilet cisterns and poor tap hygiene

How should we manage Infrequently used outlets?

Ensure staff have received adequate Legionella training and are aware of the risks when flushing and why they are flushing, ensure they are aware of the increased likelihood of biological discharge from the outlet and that they should consider safe purging of the outlet before opening the outlet fully.

On finding an unused outlet staff should never be encouraged to simply flush it, however, report it and once assessed it should be managed by safely purging the contents – the best practice is to consider using a mask or shield. Work safe, Stay Safe!

If flushing filters, always open the filters on the outlet side first, and use a cloth or bag over the compression or push-fit joint to prevent spray. Always test-fit any new or cleaned filter housing before fully opening the isolation valve.

Review their need and function – If Possible, remove or change of use

Evaluate, measure, and set quality water standards to be achieved, consider reducing any storage volumes to improve turnover. Ensure the maximum storage is set to operational use i.e., if the work is from 6am to 6pm ensure the water turns over at least once in this period, not 24 hours.

Ensure water safety records offer more than a record of attendance, vary the attendance time and flushing time to ensure usage can be evaluated fully.

Review the impacts of flushing, re-evaluate the task, adjust the time spent flushing or introduce additional monitoring or frequency.

Ensure staff undertake the task by following good water hygiene practices, and prevent cross-contamination from operative tools or surroundings.

Consider UK water usage targets - look to incorporate this into the storage volumes being set i.e., UK water is looking for a reduction of 50% by 2030 to remove the 50% variance routinely added to storage to cover peak demand.

To enhance your reading further, see our blog post> Keep calm and carry on flushing

Feel free to reach out if you have any questions about the issues mentioned above or if you would like to consult with one of our experts on water hygiene.

Editors Note: The information provided in this blog is correct at the date of original publication – November 2022.

© Water Hygiene Centre 2022