This week’s blog is a guide to cold water cisterns, their design, configuration and varying standards. Guidance for cold water cistern design primarily is given in the Water Supply (Water Fittings) Regulations 1999, but further guidance is given in the HSE’s HSG 274 Part 2 and the Department of Healths’ HTM04-01.

Below is a guide to help understand the differing standards of cold water cisterns and associated equipment.

Each ‘Feature’ of a cold water cistern will represent varying ‘standards’ or ‘practices’ and therefore risks to water quality. This table shows these differing standards for each feature, from ‘Outdated Practice’ highlighted in red to ‘Best Practice’ in blue. Outdated practices should not be targeted or found in any building and on any system, and in some instances will not meet current water regulations, for example, no lid fitted. ‘Conventional Practice’ features are examples expected on a system in a non-healthcare building such as a school or office. ‘Good Practice’ is a standard up from ‘Conventional’ and expected in most healthcare settings, however, if ‘Best Practice’ is targeted, features in the blue column should be considered.

| Feature | Outdated Practice (Fig. 1) |

Conventional Practice (Fig. 2) | Good Practice (Fig.3) | Best Practice (Fig. 4) |

| Number of Cisterns | More than 2 linked | More than 2 linked | Two linked | Single cistern |

| Inspection Hatch (>1000 I) | Not Fitted | Fitted | Fitted | Fitted |

| Heat Gain | Prone to heat gain from ambient temp | Plant room with ventilation | Plant room with ventilation | Purpose built cool cistern room |

| Flooding Risk | Location with history of flooding | Potential risk with controls in place | Potential risk with controls in place | Not prone to flooding |

| Cistern Sizing | >12 hours supply | Minimised and <12 hours supply | Minimised and <12 hours supply | Minimised and <12 hours supply |

| Multiple Cistern Configuration | Linked in series | Linked in parallel | Linked in parallel | n/a |

| Inlet Type | Inlet below water level | Conventional ball valve | Delayed action valve / level controls | Delayed action valve / level controls |

| Cistern Construction Material | Non-WRAS material or lining | Galvanised Steel | Plastic or GRP | Plastic or GRP |

| Cistern Insulation | None fitted | Supplementary insulation | Pre-insulated | Pre-insulated |

| Pipework Insulation | None fitted | Fitted | Fitted | Fitted |

| Lid Vent | None fitted | Fitted with insect screen | Fitted with insect screen | Fitted with insect screen |

| Cistern Integrity | Holes in lid or cistern | No holes | No holes | No holes |

| Cistern Lid | None or ill-fitting | Lid fits | Lid fits | Lid fits |

| Overflow Pipe | None fitted /without insect screen | Fitted with insect screen | Fitted with insect screen | Fitted with insect screen |

| Warning Pipe (>1000L) | Non fitted / without insect screen | Fitted with insect screen | Fitted with insect screen | Fitted with insect screen |

| Flow Across Cistern | Inlet and outlet on same end | Inlet and outlet on adjacent sides | Inlet and outlet on opposite sides | Inlet and outlet on opposite sides |

| Hot Water Vent | Discharges in cistern | Discharges in to tundish | Discharges in to tundish | Discharges in to tundish |

| Internal Supports | Hollow supports or baffle plates fitted | Solid supports | Solid supports | Solid supports |

| Cistern Labelling | None fitted | Cistern identification fitted | Cistern I.D and volume fitted | Cistern I.D, volume and purpose fitted |

| Cistern Pipework Labelling | None fitted | Pipework labels fitted | Pipework and valve labels fitted | Pipework and valve labels fitted |

| Deadlegs to drained cistern | Valve positions create deadleg >2 pipe diameters | Valve positions create deadleg >2 pipe diameters | Valve positions create deadleg >2 pipe diameters | Valve positions create deadleg >2 pipe diameters with vents & drains fitted |

| BMS Sensors Fitted | None | Storage temperature | Storage, inlet and outlet temperatures | Storage, inlet, outlet & sentinel temperatures |

| Booster Set Pump Switchover | Manual | Automatic weekly | Automatic daily | Automatic on-demand |

Although this guide has been inspired from guidance published in the documents stated at the start of this blog, some are professional opinions only, including the interpretation of terms ‘Outdated’, ‘Conventional’, ‘Good’ and ‘Best’ practices.

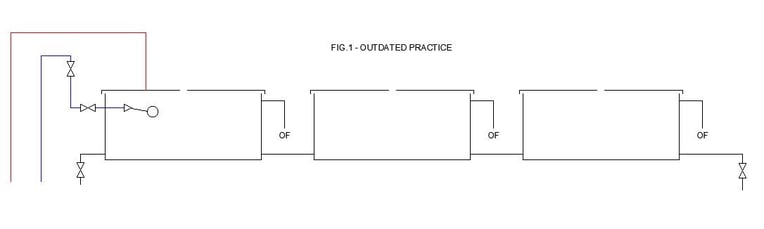

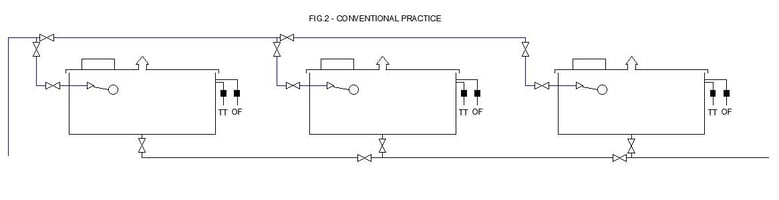

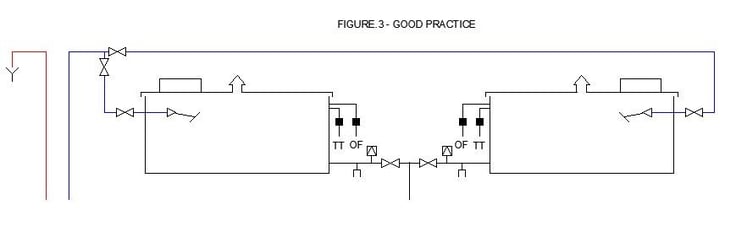

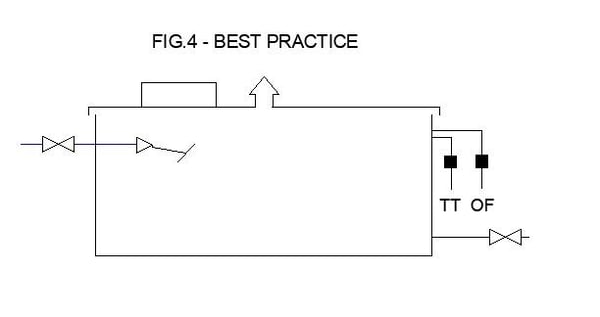

The drawings below illustrate these different standards pictorially.

Figure 1. ‘Outdated Practice’ shows multiple cisterns linked in series, no insect screen, holes in the cistern lid, open vent discharges into cistern.

Figure 2. ‘Conventional Practice’ shows multiple cisterns linked in parallel, conventional float valves, insects screens fitted, inlets and outlets adjacent, isolation valves fitted to eliminate deadleg risk.

Figure 3. ‘Good Practice’ shows 2 cisterns linked in parallel, delayed action float valves, insects screens fitted, inlets and outlets opposite, open vent redirected to tundish and drain, vents and drains fitted to interconnecting pipework.

Figure 4. ‘Best Practice’ shows a single cistern, delayed action float valves, insects screens fitted, inlets and outlets opposite, optimised capacity.

This guide could be used to check if your current cold water cistern meets expectations and then suggest where improvements can be made.

When installing new systems, cold water cistern manufacturers may have their own solutions, but essentially a cold water cistern should be designed so that cold water is kept cold, kept clean and kept moving.

If a new system is being installed, it would be advisable to aim for ‘Best Practice’ in all instances. Where cold water systems are concerned, this may be eliminating cold water storage all together, particularly for risk mitigation. This guide may act as a checklist when designing a new cold water system, to help get it ‘right first time’.

Editor’s Note: The information provided in this blog is correct at date of original publication – September 2020.

© Water Hygiene Centre 2020